[2007-07-18] Puzzle shelves

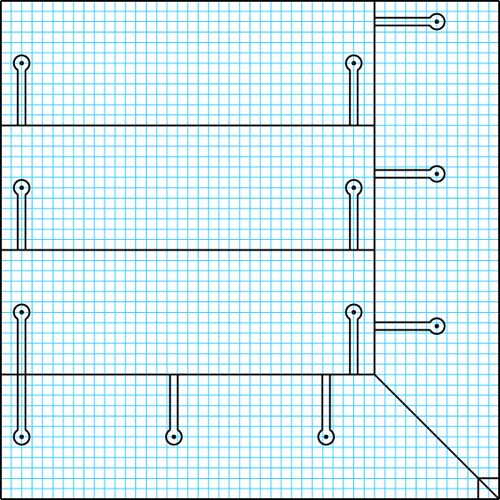

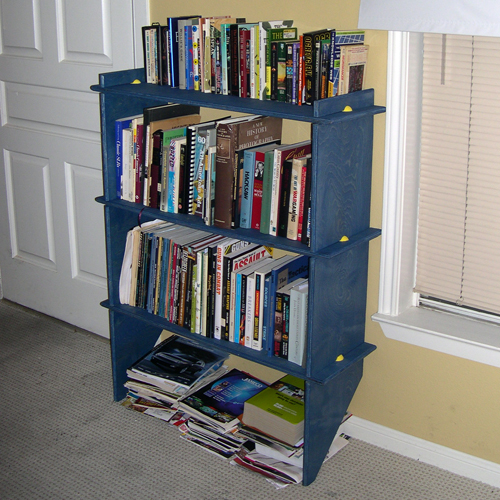

This is a half-height bookshelf made from 5 pieces of 3/4" plywood cut from a 4x4' blank according to the plan below. This prototype was made from Finnish plywood, stained with Minwax "Island Water," and treated with boiled linseed oil. Click here to download the plan in .DXF format.

The parts have been designed to minimize wastage in the parts blank while maximizing available shelf space. The puzzle shelves unit can stand up against a wall to provide a "fourth shelf" below the other three, or it can be turned over and stand on its own.

This design is conceptually related to my earlier puzzle chair and puzzle table. Additionally, the prototype includes a new experimental locking halved joint which uses a foam rubber ball to keep the joined members together. The plan could easily be modified to use conventional halved joints.

Instead of flat slot-ends, the slots in the puzzle shelves unit are terminated with hole-saw cuts, giving the finished slot a kind of "keyhole" shape. When two slotted members are halved together, a spherical void is formed by the perpendicular overlap of the round cuts. A foam rubber ball, in this case a practice golf ball from the sporting goods store, is popped into this spherical recess from an oblique angle, locking the two members together and cushioning their motion against one another.

As implemented, this joint is only partly successful. Either the foam is too stiff or the balls are too large or the holes are too small. Considerable force was required to get the foam balls into position once the pieces were assembled, and it seems unlikely that the shelves can be taken apart again without cutting or dissolving the foam balls away. Tweaking one of the variables listed above could probably remediate the problem. Also, the use of slightly angled or "sloped" corners on the slots might help to ease assembly, although it would provide no help with the disassembly problem.

Another advantage of ending the slots with hole-saw cuts is that it is much easier to cut a circle in a panel with a hole saw than it is to cut a flat, square end of a slot. The former operation can be completed with two straight saw cuts and a drill, whereas the latter requires the use of a chisel and a hammer and takes considerable time and attention to achieve good looking results.

last modified 2007-07-18